<< ROTATING EQUIPMENT ENGINEERED SOLUTIONS AND SERVICES

POWER GENERATION

PLANT LOCATION: AUSTRALIA – BARROW ISLAND – GORGON LNG

PROJECT DESCRIPTION

Gorgon project is one of the world’s largest natural gas projects and the largest single resource natural gas project in Australia’s history.

A part of project contemplete the installation of five generator driven by gas turbine MS9001E DLN1.

PROJECT DEVELOPMENT

Turbine Control Panel manages machine protections, machine auxiliaries and utilities start and stop sequences, process valves, machine start-up and stop sequences, speed controller thought the control of fuel, internal overspeed protection, electrical power control.

A particular algorithm is implemented to control the exhaust quality (DLN1).

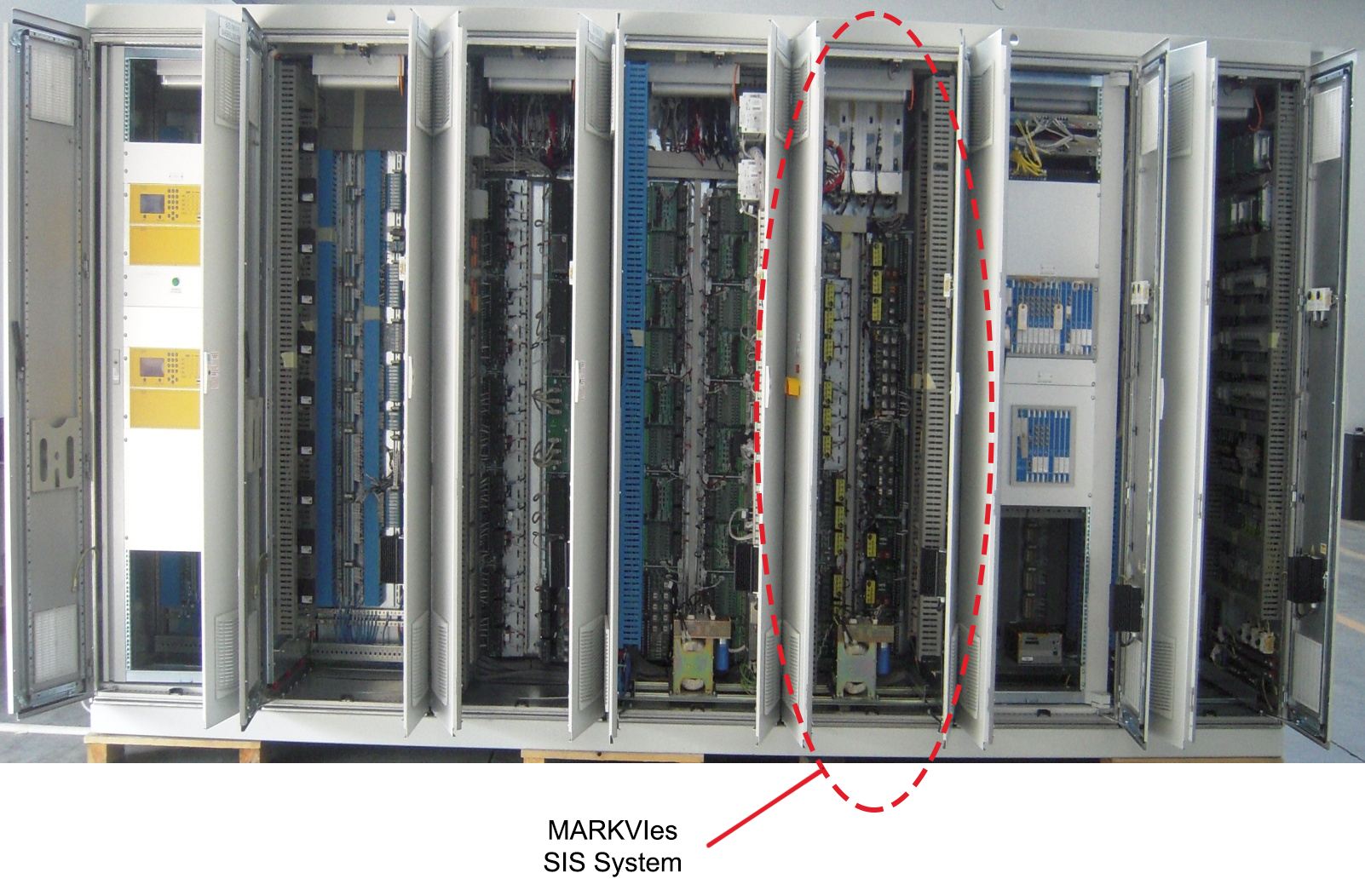

There are two control system installed on TCP. GE MarkVIe controls turbogenerator machine and GE MarkVies manages the critical trips involved in safe. MarkVIes, in fact, is designed according IEC61508 “Functional Safety of programmable electronic safety system” to achieve, depending MarkVIes configuration, Safety Integrity Level 3 (SIL3).

MarkVIes than can be used as Safety Control System in Safety Instrumented System (SIS) which includes Safety Shutdown System and Emergency Shutdown System.

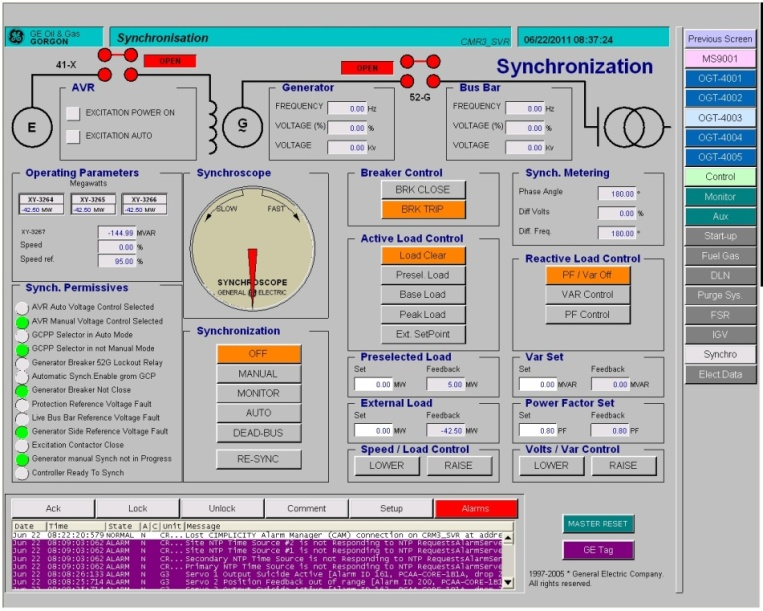

MarkVIe control system manages synchronization operations to close Generator Breker (52G). Electrical parameters are acquired make the use of MarkVIe specified modules.

MarkVIe control system manages synchronization operations to close Generator Breker (52G). Electrical parameters are acquired make the use of MarkVIe specified modules.

For this project SSE supplies the five Turbine Control Panels (one per turbogenerator). SSE technician partecipated on gas turbine tests in Customer test area.

TECHNICAL DATA

| SUPPLY | Four Unit Control Panel to control generators driven by gas turbines. |

| CONTROLLER | GE Mark Vie and GE Mark VIes |

| SUPERVISION | General Electric Cimplicity SCADA system |

SUMMARY

SSE operates in the field of industrial control solutions and undertakes the design, software development, production and commissioning of Control & Supervisory Systems for the Oil & Gas and Power Generation Industries. SSE main task is to provide and service Control and Supervisory Systems for rotating machinery and associated auxiliary systems.

The controller normally used in these applications is the PLC.

Following the list of PLC generally used in our applications:

- General Electric Intelligent Platform – 90/30, 90/70, Rx3i, Rx7i series

- Siemens – 300, 400H, 400HF series

- Rockwell Automation – RsLogix 5000 series, PlantPax

- Foxboro – Triconex, Trident

- Telemecanique – Premium

- HIMA – Himax

- Woodward – Micronet plus, regolatori 505, 5009

Anyway, on gas turbine control applications, dedicated PLC are normally used:

- General Electric – MarkVIe

- General Electric – MarkVI

- General Electric – MarkV,

- Woodward – Micronet plus

At least one HMI (Human Machine Interface) is normally developped for control panel.

SSE make use of SCADA (Supervisory Control And Data Acquisition) supervision software to develop HMI. Following the main supervision software used:

- General Electric – Cimplicity

- Siemens – Wincc

- Rockwell Automation – RsView, FactoryTalk

- Intouch – Wonderware

HIGHLIGHT

- Integrated system to control machine and to manage the safe signals.

- Synchronization phase managed by Control Panel

BENEFITS

- Cost Reduction

- Less need for panel installation space in control room